1. Key Challenge

The organization encountered a major challenge due to leaks in its compressed air system, resulting in continuous energy loss and elevated operational expenses.

The company identified that a considerable portion of the compressed air produced was not being used efficiently in production, which impacted its performance and profitability.

2. Implemented Solution

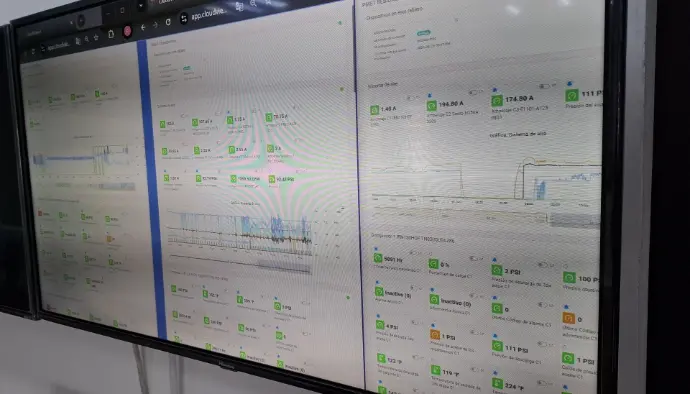

Through a comprehensive analysis using CloudView+ (Remote monitoring tool), existing leaks in the system were identified and categorized. Strategic repairs were subsequently carried out to minimize losses and optimize compressed air consumption.

3. Results

The benefits became evident after the validation of the improvements:

✅ Reduction of Air Waste from 25% to 5.8%

✅ System Improvement by 76.8%

✅ Annual Savings of $77,325.92 MXN

✅ Prevented 13.50 Tons of CO₂ Emissions Annually

✅ Saved 33,753.6 kWh of Energy

Prior to the repairs, leakage losses amounted to $100,684.8 MXN annually. Following the interventions, this figure dropped to just $23,051.52 MXN, delivering an immediate and measurable financial benefit.

4. Conclusion

Thanks to the optimization of the compressed air system and the implementation of targeted solutions, a significant reduction in operating costs and an improvement in energy efficiency were achieved.

This case demonstrates how a detailed analysis and appropriate repairs can generate substantial savings and deliver immediate results.