Monitoring and control

What is?

That your production does not stop, the online monitoring service of your equipment allows you to know remotely in real time the important conditions or variables of your compressed air system. We help you predict and prevent any failure as much as possible.

What benefits does it have?

Reduce the time or moments of inactivity of your systems.

Know the performance and status of your machines.

Advance maintenance scheduling.

Real-time analysis of performance

How do we do it?

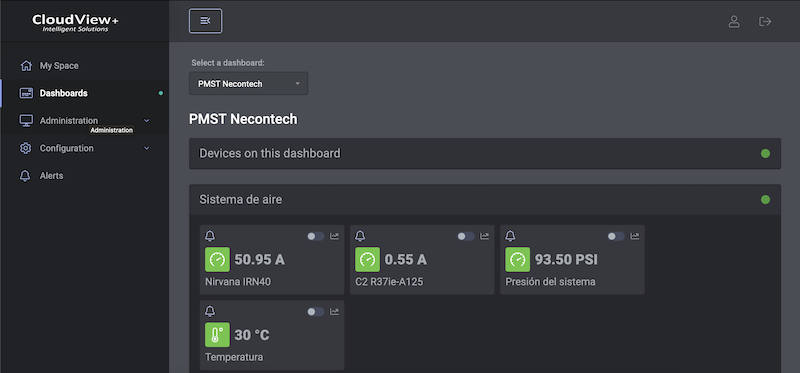

We show you an online platform with multiple users and important variables to monitor and control your compressed air system in real time.

We include a current meter in each of your compressors, in addition to a pressure sensor in the system tank, in order to have a remote reading of: amperage, voltage, pressure and ambient temperature, and a variety of parameters with the protocol modBus communication depending on the controller that your equipment has.

What includes?

Access to our web monitoring platform.

Alert reports via email.

Monthly report of incidents and electrical/mechanical conditions in the air system and energy saving status.

Platform use training.

Accompaniment by a specialized monitor.

Technical support regarding platform and connectivity.

Oriented and specialized recommendation in areas of opportunity of the plant.

Additional services:

Vibrations in the engine.

Flow in compressed air system.

Dew point.